Truck & SUV Brake Pads - Ultimate Duty Brake Pads

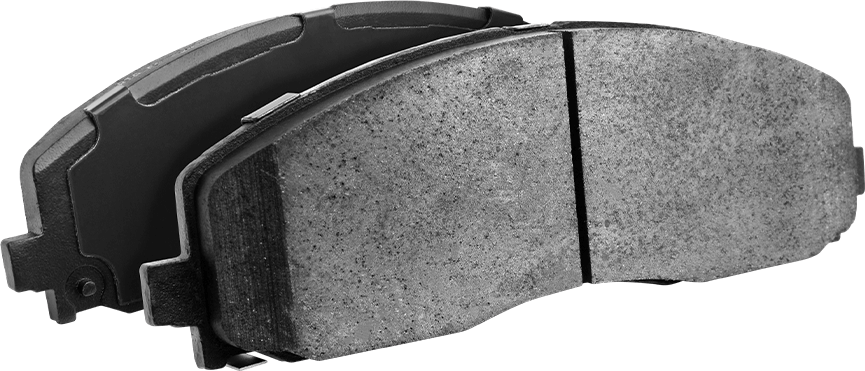

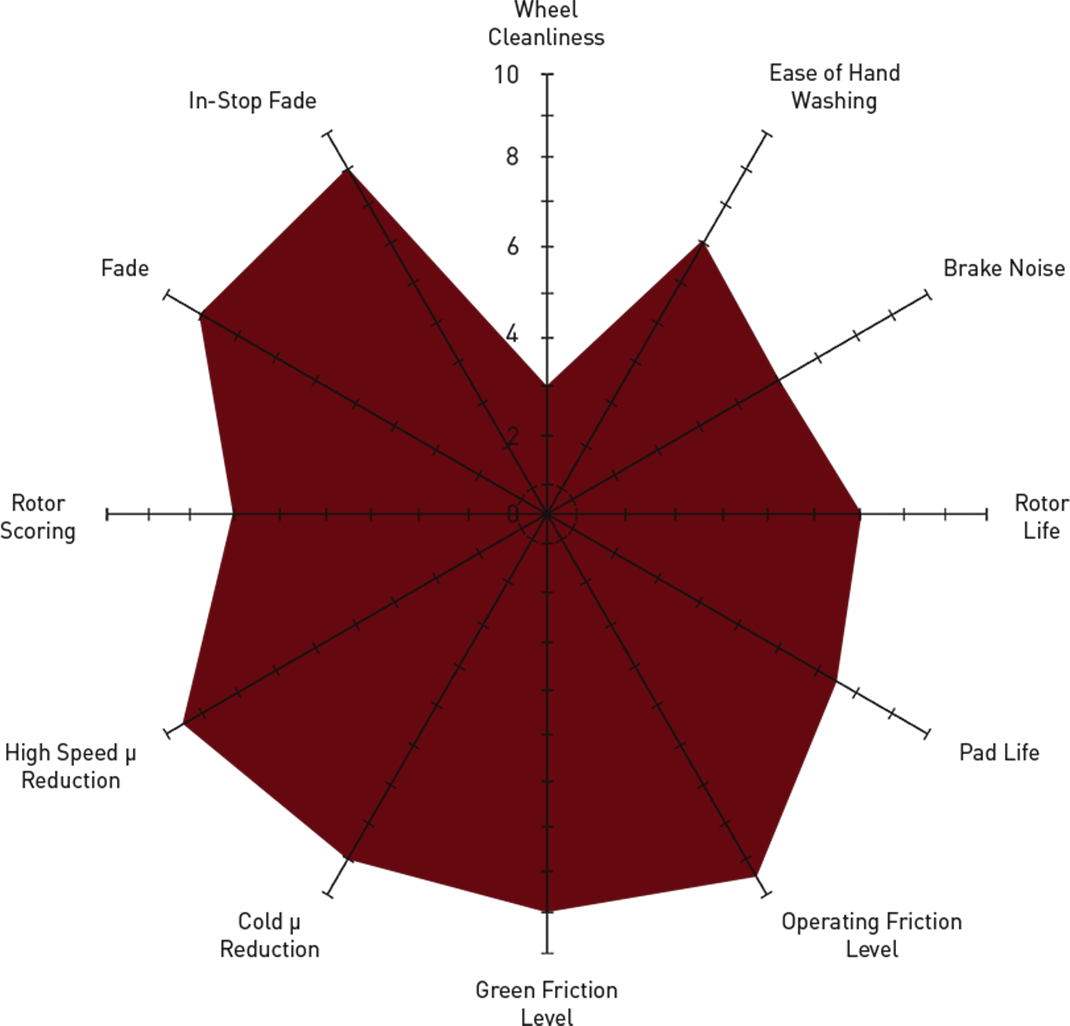

Be ready for anything and anywhere. Designed for the Ultimate Trucks and SUVs with larger wheels or tires, and modified suspension. DFC Ultimate Duty Performance Brake Pads deliver exceptional braking performance in any condition. These pads are exclusively engineered and formulated to withstand extreme heat, heavy duty operation, frequent stopping, off-roading, or towing.

DFC Active Performance Brake Pads are manufactured using the latest friction technology and extensively tested under extreme conditions. Excellent friction stability and consistency coupled with very good modulation, threshold control, and release characteristics over high operating temperature ranges. DFC’s proprietary friction materials can operate from temperatures of –30° Fahrenheit to 1400° Fahrenheit and offers a high friction coefficient (0.40μ to 0.68μ) with high resistance to brake fade.

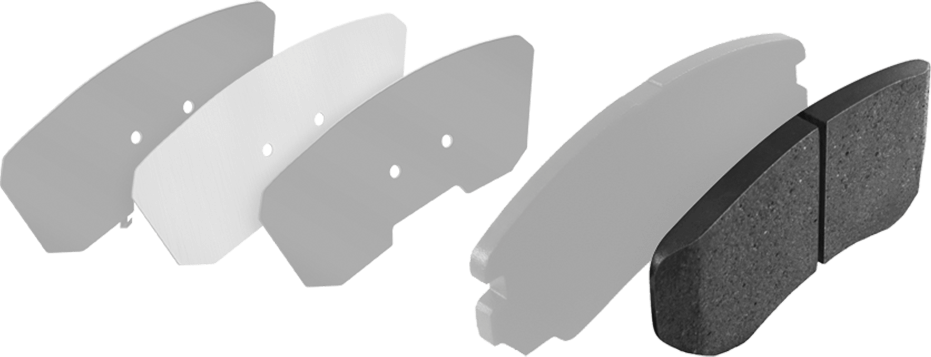

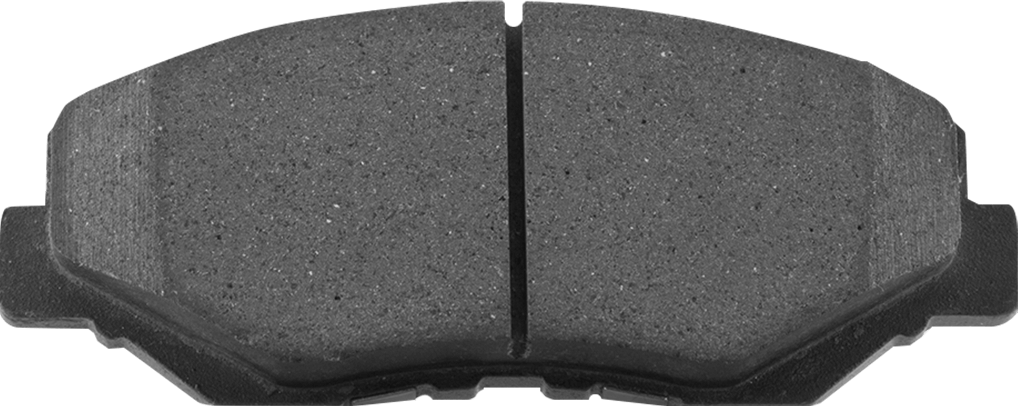

All DFC Brake Pads are 100% post cured to ensure stable friction performance. Each pad is then scorched to remove uncured bonding agents to minimize the need for initial break‐in period and increase stopping power from the initial stop.

Lastly, the pads assembled with DFC Premium Rubber‐Steel‐ Rubber shims for improved NVH (noise, vibration, and harshness) characteristics.

- Designed for Trucks and SUVs with bigger wheels or tires, and modified suspension. Great performance for off-roading and towing.

- Offers high friction coefficient and low compressibility

- Delivers unmatched braking performance, pedal response, and superb brake control

- High resistance to brake fade at high operating temperature ranges

- Extremely High Torque with Aggressive Initial Bite

- Excellent Friction stability and consistency

- Outstanding Modulation, Threshold Control, and Release Characteristics

- DFC Ultimate Duty Performance brake pads use a high performance friction material to deliver superior braking performance under all driving conditions. This material formulation has a high friction coefficient and low compressibility, which may produce brake noise and dust on some vehicles.

- Chamfered and Slotted (where applicable) to reduce noise when braking

- Scorched to remove uncured bonding agents, minimizing the need for initial break-in period and increasing stopping power from the initial stop.

- Positive mold to promote consistent friction material density

UNITED STATES

UNITED STATES