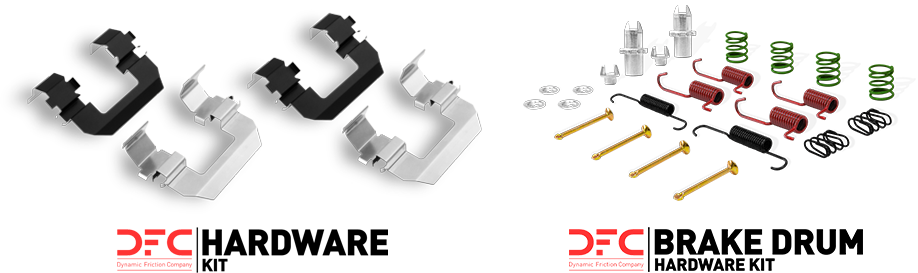

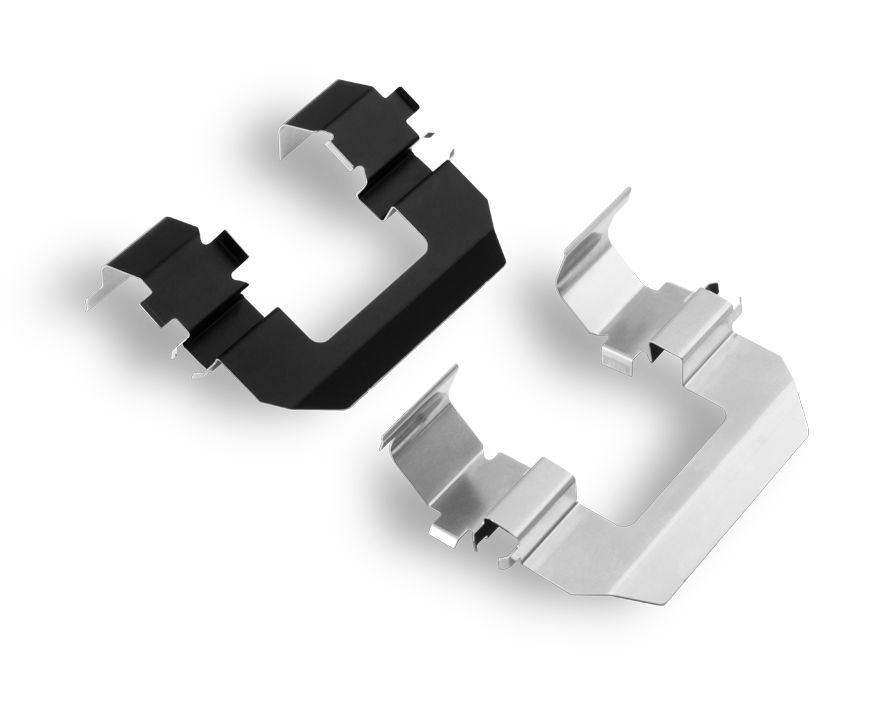

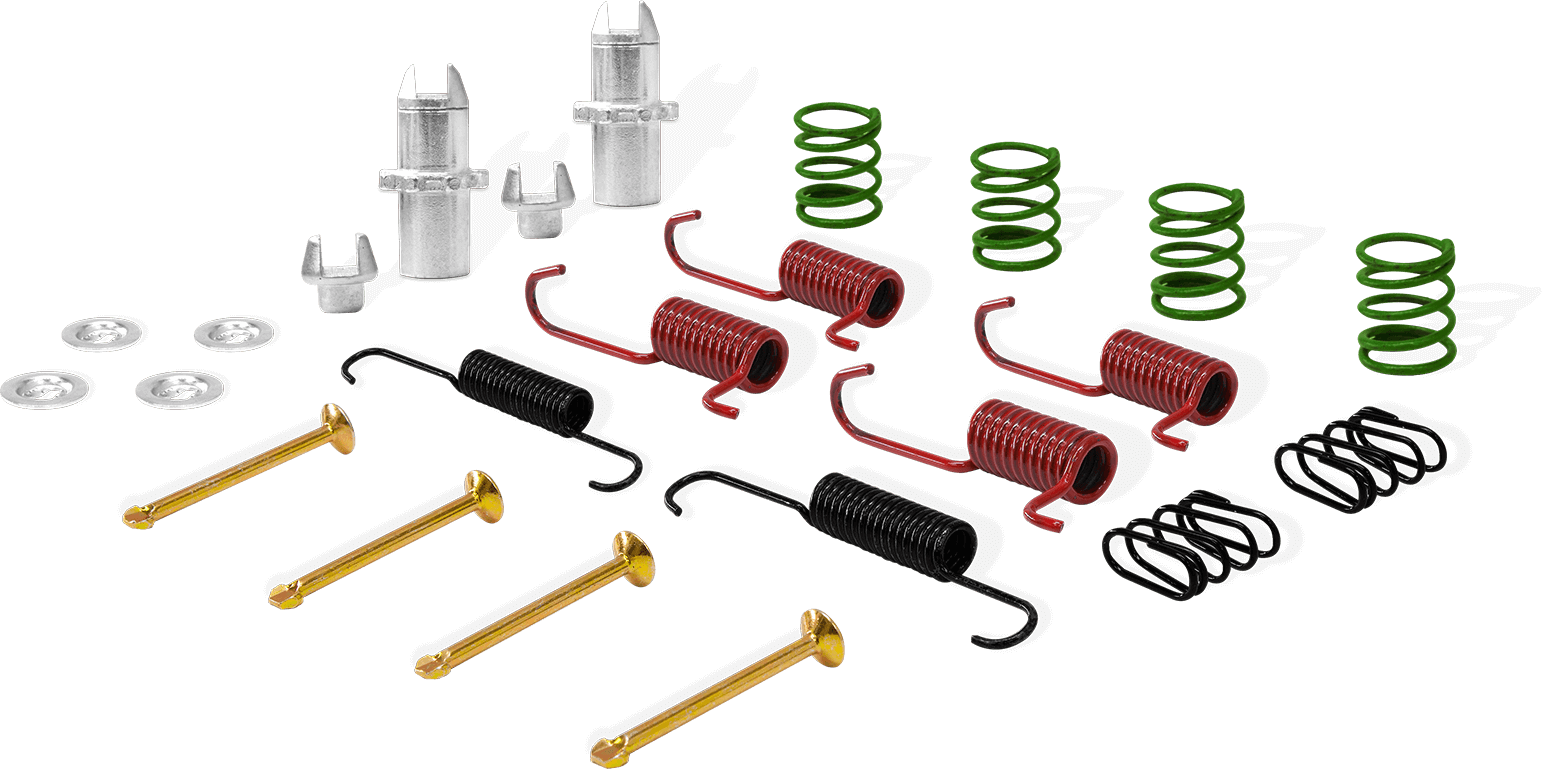

Durable Hardware Kits

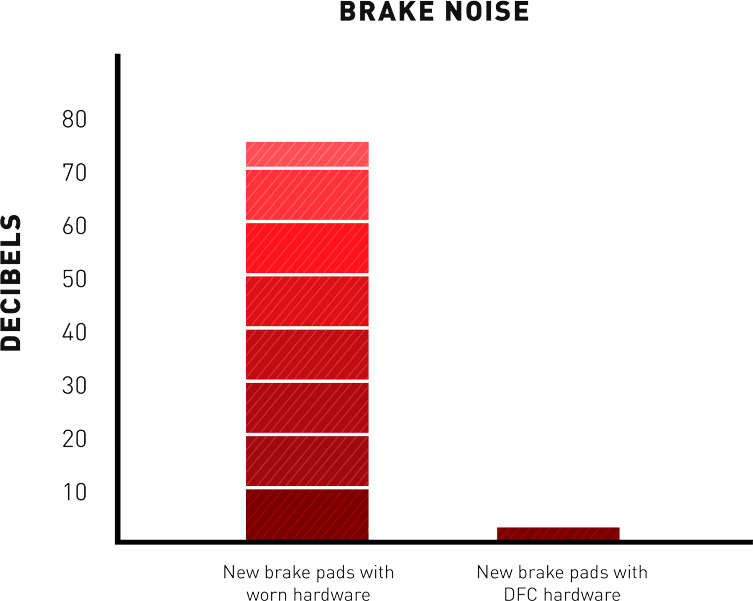

Often overlooked during a brake repair, the disc brake hardware can be stressed, fatigued, or corroded within 1-2 years, which leads to a reduction in spring tension, excessive caliper movement, premature/uneven wear, and noise.

- Sold as Axle Kits, not per side

- Designed specifically for each application

- Reduces noise/ vibration and premature wear

- Eliminates heat and corrosion deterioration

- Minimizes drag to improve fuel efficiency

- Rubber Coated Abutment Clips

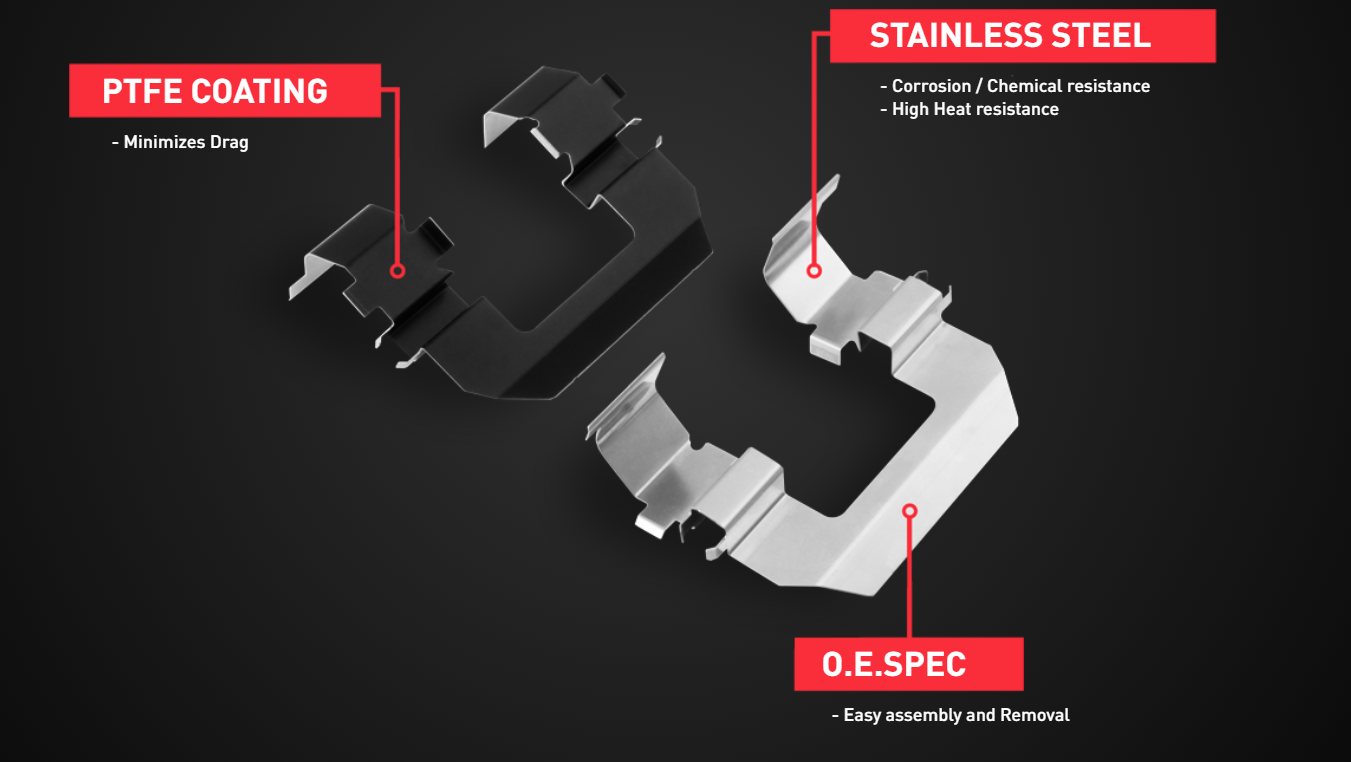

To ensure optimum braking performance and total confidence, DFC Disc Brake Hardware kits are precisely designed with the same attention to form, fit, and function as Original Equipment Manufacturers. We've combined the features of PTFE Coating, Vulcanized rubber, and stainless steel all in one hardware kit.

PTFE coatings, or Polytetrafluoroethylene are non-stick fluoropolymer coatings that use a two-coat (primer/topcoat) system. These products have the highest operating temperature of any fluoropolymer and have extremely low coefficient of friction, fair abrasion resistance and good chemical resistance.

- Corrosion resistance

- Chemical resistance

- Easy assembly & removal

- Low coefficient of friction

- High heat resistance

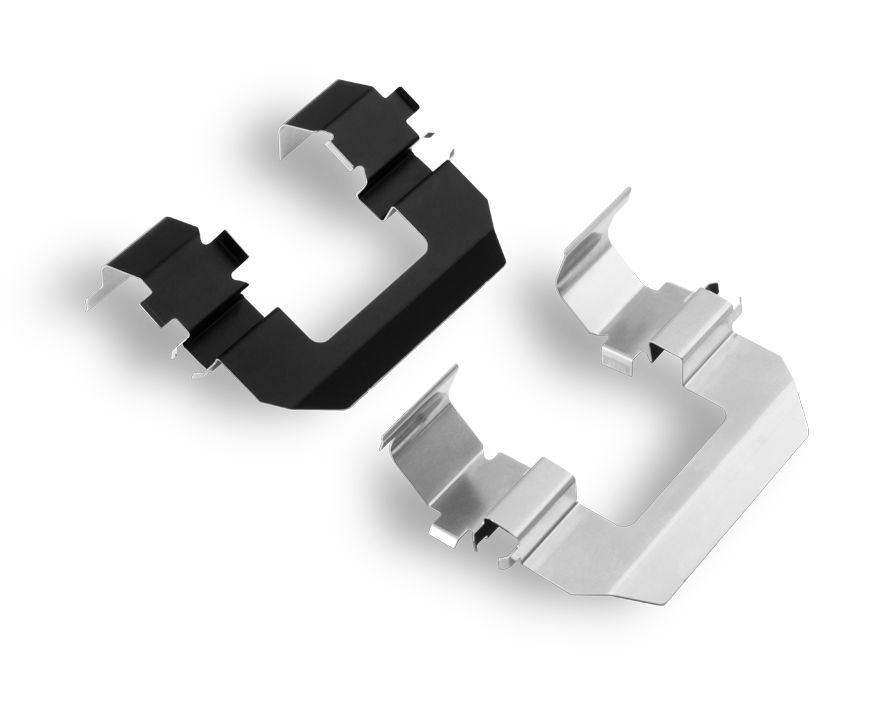

Even after changing brake pads, there may be noise coming from the brake components at every stop. Installing new DFC Brake Hardware Kits will reduce or eliminate the noise.

-

Manufactured using premium materials for

Manufactured using premium materials for

longevity and consistent performance. -

Reduces noise and vibration.

Reduces noise and vibration.

-

Prevents premature wear, providing longer

Prevents premature wear, providing longer

brake life and performance. -

Minimizes drag to improve fuel efficiency.

Minimizes drag to improve fuel efficiency.

-

Sold as Axle Kits, not per side.

Sold as Axle Kits, not per side.

-

Designed to meet the same form, fit, and

Designed to meet the same form, fit, and

function as OEM brake Hardware Kits. -

Quality tested to ensure long-lasting performance.

Quality tested to ensure long-lasting performance.

-

New in Box, Ready to Install, No Modifications Required

New in Box, Ready to Install, No Modifications Required

UNITED STATES

UNITED STATES