Corrosion Protection Coated Rotors - GeoSpec Brake Rotors

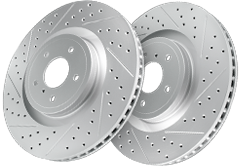

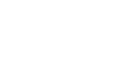

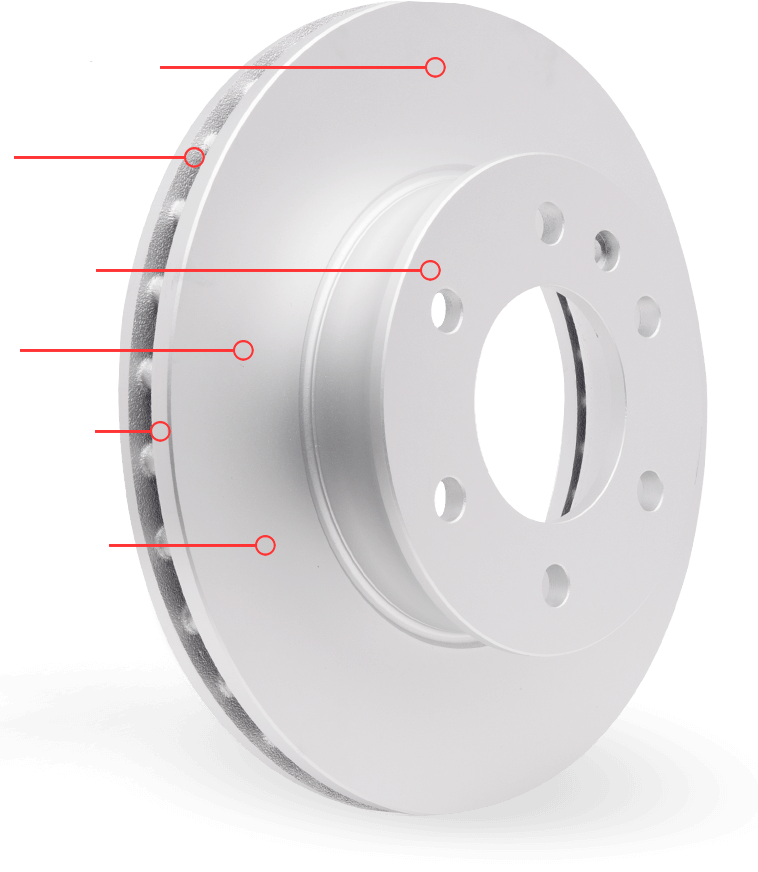

Developed to form a durable and attractive silver-gray finish, DFC GEOSPEC Coated Brake Rotors fight rust far better

than conventional paint or zinc coatings.

Each DFC GEOSPEC Coated Brake Rotors is processed dry, shipped dry, and ready to install without any additional

preparation. An average brake job takes 1.25-2.5 hours per axle. Without the need to clean an oil covered rotor, this saves a tremendous amount of time and money during the installation process. The coating is simply and

safely swept away by the friction material with no harmful effects.

tightest tolerances available in the market today. Then, the rotor is prepared with a non-directional

finish to promote a faster and more even brake pad bed-in, along with quieter and smoother stops.

of the art electronic mill-balance process.

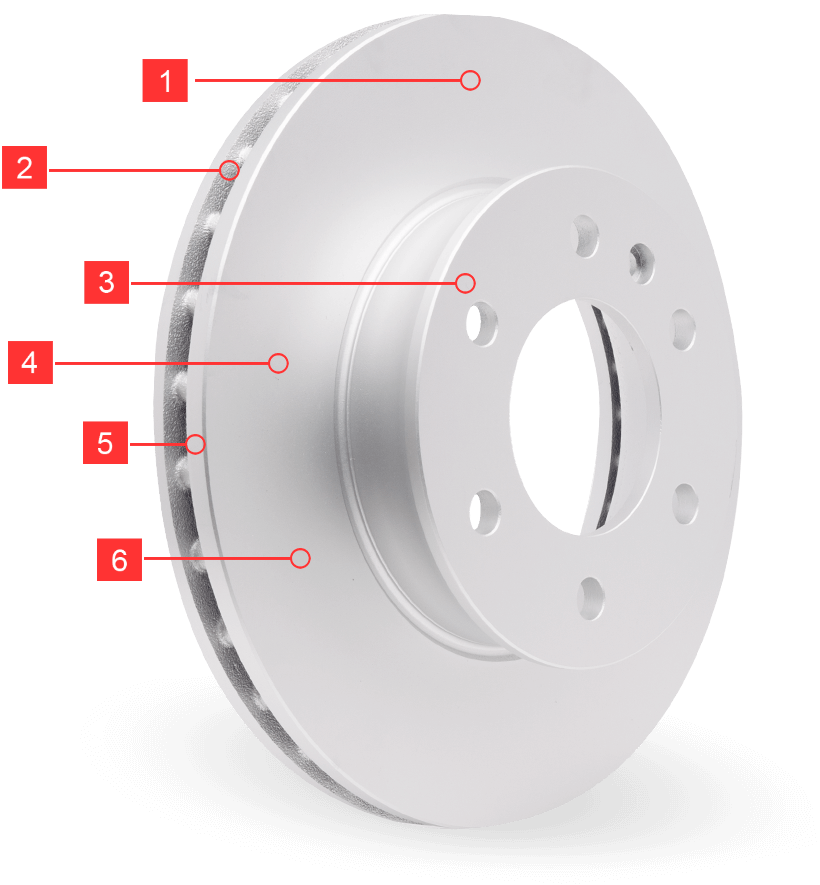

- Engineered with premium G3000/G11H18 iron castings for strength, stability, and durability.

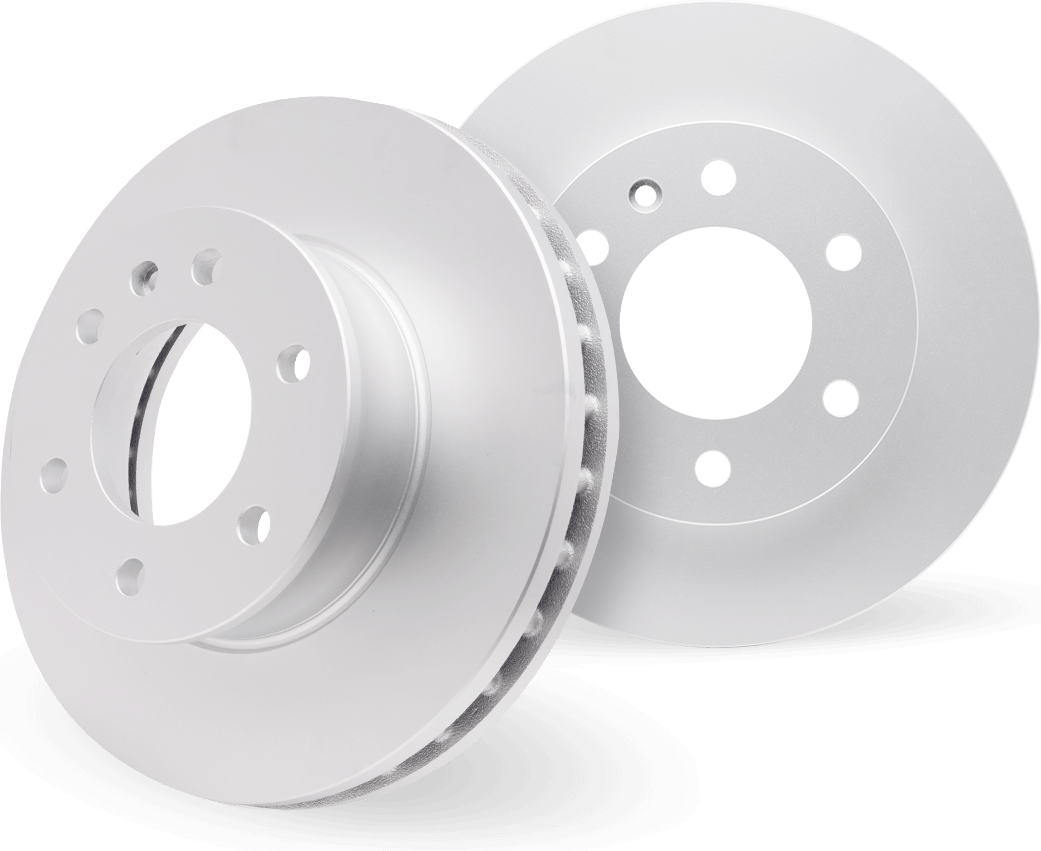

- Original Equipment (OE) vane configuration to ensure proper and maximum heat dissipation.

- Provides superior corrosion protection over zinc / conventional painting

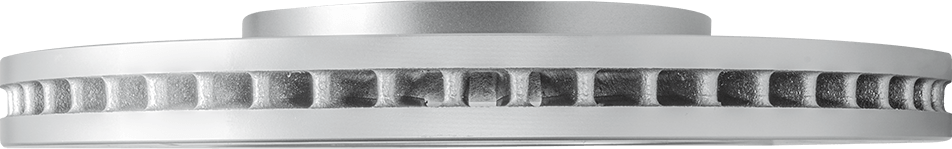

- CNC-machined to the tightest tolerances.

- 100% precision cut and mill-balanced for smoother stopping and zero vibration at any speed.

- Non-directional finish to promote faster break-in and smoother stops.

- Designed to meet the same form, fit, and function as OEM brake rotors.

- Ready to Install - No additional pre-degreasing preparation needed (saves time and money during installation process).

- Quality tested to ensure long-lasting performance.

- No Modifications Required.

UNITED STATES

UNITED STATES