Performance Brake Pads For Agressive Driving - Active Brake Pads

DFC ACTIVE PERFORMANCE

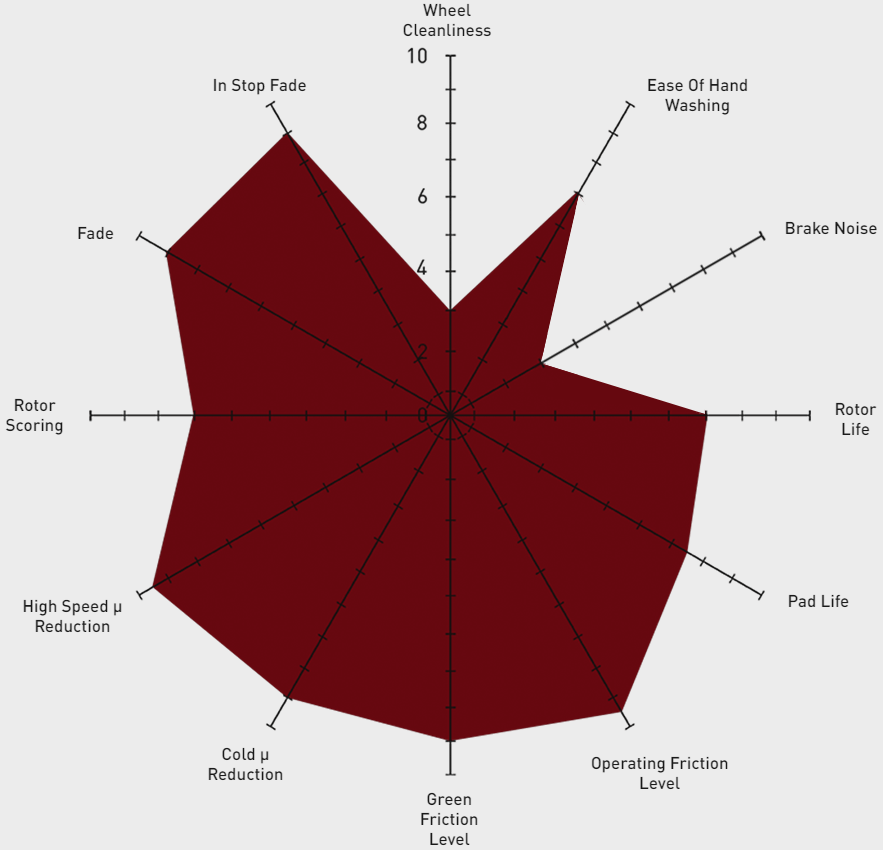

Engineered to meet the demands of the weekend offroader, high performance enthusiast, spirited street driver, and serious track racer, DFC Active Performance Brake Pads are an extremely high torque material with an aggressive initial bite and medium-high, linear rising torque curve.

HIGH RESISTANCE TO BRAKE FADE

DFC Active Performance Brake Pads are manufactured using the latest friction technology and extensively tested under extreme conditions. Excellent friction stability and consistency coupled with very good modulation, threshold control, and release characteristics over high operating temperature ranges. DFC’s proprietary friction materials can operate from temperatures of –30° Fahrenheit to 1400° Fahrenheit and offers a high friction coefficient (0.40µ to 0.68µ) with high resistance to brake fade.

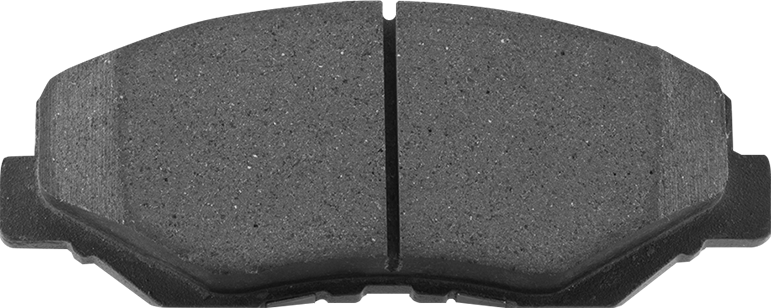

100% POST CURED AND SCORCHED

All DFC Brake Pads are 100% post cured to ensure stable friction performance. Each pad is then scorched to remove uncured bonding agents to minimize the need for initial break-in period and increase stopping power from the initial stop.

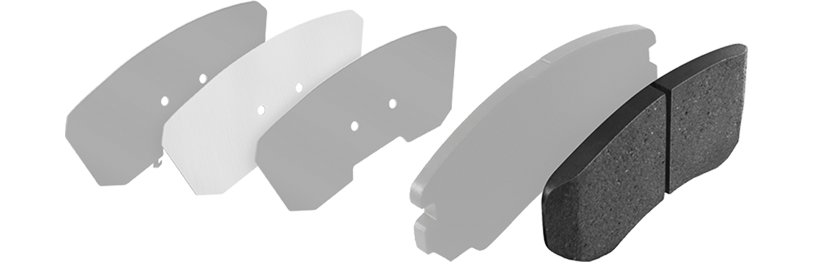

DFC PREMIUM RUBBER-STEEL-RUBBER SHIMS

Lastly, the pads are assembled with DFC Premium Rubber-Steel-Rubber shims for improved NVH (noise/vibration/harshness) characteristics.

HIGH PERFORMANCE / HIGH FRICTION FORMULATION

- Designed for the performance enthusiasts, spirited street driver, and track racers

- Offers high friction coefficient and low compressibility

- Delivers unmatched braking performance, pedal response, and superb brake control under all conditions

- High resistance to brake fade at high operating temperature ranges

- Extremely High Torque with Aggressive Initial Bite

- Excellent Friction stability and consistency

- Outstanding Modulation, Threshold Control, and Release Characteristics

- DFC Active Performance brake pads uses a high performance friction material to deliver superior braking performance under all driving conditions. This material formulation has a high friction coefficient and low compressibility, which may produce brake noise and dust on some vehicles.

OEM TECHNOLOGY WITH NOISE REDUCTION

& PERFORMANCE FEATURES

& PERFORMANCE FEATURES

- Chamfered and Slotted (where applicable) to reduce noise when braking

- Scorched to remove uncured bonding agents, minimizing the need for initial break-in period and increasing stopping power from the initial stop

- Positive mold to promote consistent friction material density

DFC ACTIVE PERFORMANCE

UNITED STATES

UNITED STATES