2018 Jeep Grand Cherokee DFC Rotors with 4000 HybriDynamic Brake Pads includes Hardware

Part Type:

Disc Brake Kit

SKU:

6814-42023

Axle:

Front & Rear

Sub model:

High Altitude, Limited, Overland, Summit, Trailhawk

Engine Base:

3.0L 2987cc 182ci V6 , 5.7L 345ci V8

PCQ:

1

Note:

Heavy Duty Brakes

Description

- The DFC HybriDynamic brake pad formulation is designed to deliver a consistent pedal feel and superb brake response at a great value, taking the guesswork out of choosing the right brake pad material. Not only does the DFC 4000 HybriDynamic Brake Pad provide superior performance for enhanced safety, but it also boasts low dust and low noise characteristics, making it the ideal choice for daily driving. All DFC Brake Pads are 100% post cured to ensure stable friction performance. Each pad is then scorched to remove uncured bonding agents to minimize the need for initial break-in period and increase stopping power from the initial stop. Lastly, the pads are assembled with DFC Premium Rubber-Steel-Rubber shims for improved NVH (noise/vibration/harshness) characteristics. DFC 4000 Brake Pads are environmentally friendly and adhere to the low copper requirements under California and Washington restrictions for 2021 / 2025

- DFC Complete Brake Kits makes it easy to get the perfect brake components all in one package. You can order front kits, rear kits, or front and rear kits. Every kit comes complete with brake rotors and pads to get the job done right the first time.

- Formulated with the G3000 cast iron specification, DFC Premium Brake rotors are engineered to match OEM specifications for durability, reliability, and stability. Each rotor casting is sent to our state of the art machining facilities, where it is processed to the tightest tolerances available in the market today. Then, the rotor is prepared with a non-directional finish to promote a faster and more even brake pad bed-in, along with quieter and smoother stops. Finally, all vented rotors are 100% inspected for balance and are corrected if necessary with our state of the art electronic mill-balance process. After all of the machining processes are completed, each rotor passes a 100% inspection station that measures all critical attributes to ensure that each rotor meets OE specifications. This further guarantees that each and every rotor delivered to you is trouble free. DFC provides a 12 month - 12,000 mile limited warranty against defects in material and workmanship.

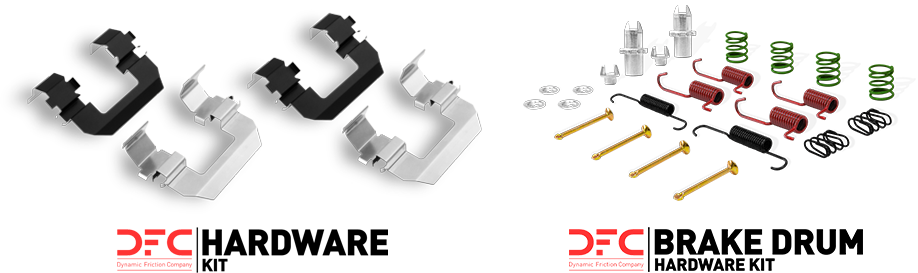

- Often overlooked during a brake repair, the disc brake hardware can be stressed, fatigued, or corroded within 1-2 years, which lead to a reduction in spring tension, excessive caliper movement, premature/uneven wear, and noise. To ensure optimum braking performance and total confidence, DFC Disc Brake Hardware kits are precisely designed with the same attention to form, fit, and function as Original Equipment manufacturers. We’ve combined the features of PTFE Coating, Vulcanized rubber, and stainless steel all in one hardware kit.

Features and Benefits

- 100% precision mill-balanced for smoother stopping and zero vibration at any speed.

- 100% Asbestos free formulation.

- Chamfered and Slotted (where applicable) to reduce noise when braking.

- Designed specifically for each application.

- DFC Premium Rubber-Steel-Rubber shims for improved NVH (noise, vibration, and harshness) characteristics.

- Designed to meet the same form, fit, and function as OEM brake rotors.

- DFC Hardware Kits - reduces noise/vibrations and premature wear. Minimizes drag to improve fuel efficiency.

- Extended Durability: Our brake pads are built to last delivering an extended lifespan that provides optimal performance and peace of mind.

- Premium Materials: We source our materials from top-quality suppliers, ensuring that our brake pads are made from the highest-quality components available.

- No modifications required.

- Engineered with premium G3000/G11H18 iron castings for strength, stability, and durability

- Scorched to remove uncured bonding agents, minimizing the need for initial break-in period and increasing stopping power from the initial stop.

- Non-directional finish to promote faster break-in and smoother stops.

- Quality tested to ensure long-lasting performance.

- Silver Zinc Plated for corrosion protection..

- Quiet Operation: Our Brake pads are engineered to reduce noise and vibration, delivering a smooth, silent ride every time.

- Rubber Coated Abutment Clips.

- Stainless Steel Material - Eliminates heat and corrosion deterioration.

- Superior Stopping Power: Our brake pad is designed to provide excellent stopping power, ensuring that your vehicle comes to a safe and reliable stop every time.

Product Specifications

| Description | Value |

|---|---|

| California Proposition 65 | This product contains Antimony Oxide and other chemicals which is known in the State of California to cause cancer ( or reproductive problems). |

| Weight | 105.65LB |

UNITED STATES

UNITED STATES